Construction equipment engineering

The term “DesiUS” stands for “disintegration ultrasound system”. The disintegration process which forms the basis of DesiUS was developed by Weber Ultrasonics in collaboration with the Fraunhofer Institute, and was optimised by Weber Entec through the use of the BioPush reactor.

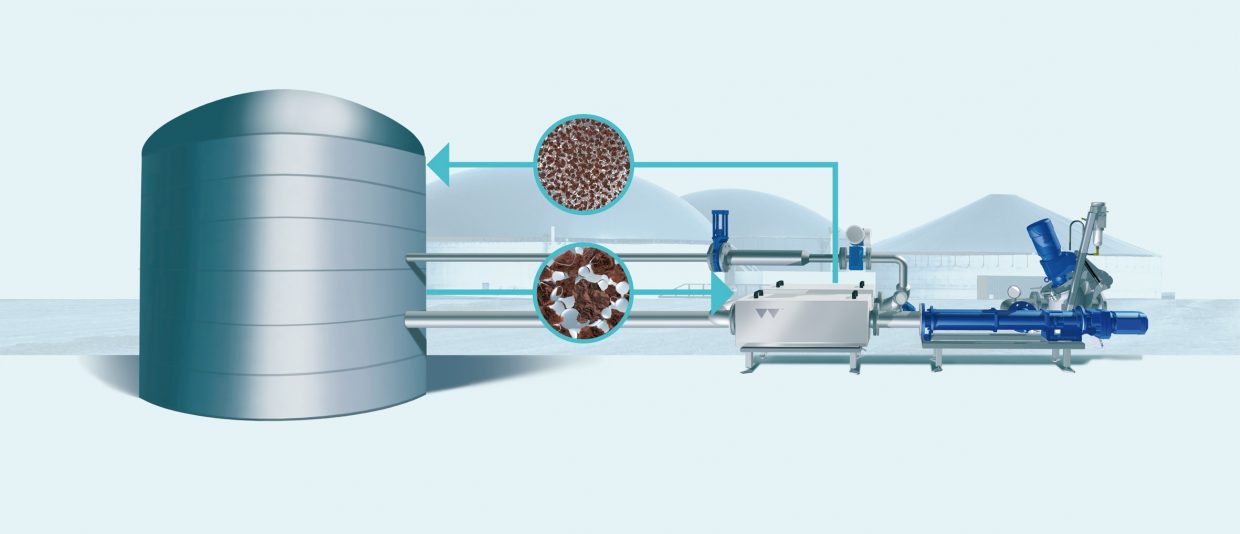

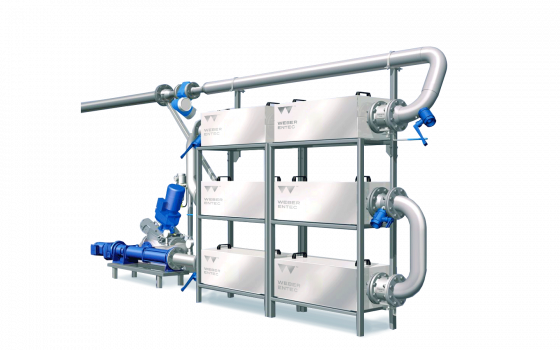

DesiUS (Disintegration Ultrasound System) represents energy-efficient and process-robust cell opening technology combined with exceptionally high efficiency. The robust and completely maintenance-free construction of the BioPush reactor allows a simple and uncomplicated structure. The ultrasonic reactors of the turnkey constructed plant are charged via a screw pump. The substrate is routed through the sound field at a specific speed in such a manner that the specific energy input required for treating the substrate is ideally achieved. A macerator protects the machine from foreign objects and provides coarse homogenization upstream, in order to achieve optimal coupling of the ultrasound. A PLC-supported control system enables robust and trouble-free operation. In addition, the machine is equipped with sensors that monitor temperature, pressure and volumetric flow.

Technical advantages

- Very high energy efficiency – 50 % saving compared to other disintegration systems

- Extremely low-maintenance plant technology

- High degree of operational reliability

- Long standing times

- Can be ideally adapted to the respective requirements

- Lower space requirement thanks to compact design, simple plug & play installation

- Quick pay back

Possible integration examples

Advantages BioPush

LONG LIFETIME, OPERATIONAL RELIABILITY and ZERO MAINTENANCE

The BioPush Ultrasound reactor solves the problems of the other disintegration systems. Because biomasses with a typical solids content between 8 % and max. 13 % have a relatively high viscosity, more effort is usually required in traditional plants in order to ensure an effective coupling of the ultrasound to the medium. Because the cavitation performance of the ultrasound becomes more damped as the viscosity of the medium increases, the medium must therefore be passed as close as possible to the sonotrode. Although this could be achieved constructionally by means of a sufficiently small pipework cross-section, it is not possible to implement it in this way, because the sonotrodes tend to become affected by blocking and “tressing” from fibrous components, both in substrates from biogas plants using renewable raw materials and also in sewage sludges. The results are a high level of sound damping, and therefore reduced energy efficiency.

The BioPush reactor developed by Weber Entec specifically for the treatment of biomasses tackles this problem. The structure practically precludes blockages and tressing. The working life of the BioPush reactor is several times longer than with classical rod sonotrodes in the biomass area.

The Biopush reactor

What is so special?

The core technology of DesiUS is the ultrasonic technology from Weber Ultrasonics. The BioPush reactor, which was specially developed for the treatment of biogenic sludges, takes into account the high requirements placed on the disintegration process and in many aspects is significantly better than the conventional rod transducer or sonotrode technique.

In the early days of ultrasonic disintegration, the use of the rod transducers technology turn to be problematic because of the enormous wear and the use of the sonotrodes in the biomass field.

These findings led to a rethinking at Weber Entec and Weber Ultrasonics. A reactor specifically designed for the treatment of biomass has been developed.

The problems of traditional rod oscillator technology listed below arise mainly because of the direct contact of the sludge with the rod transducer. The aggressive cavitation force, which is wanted and required to achieve the intended effect, inevitably leads to an unstable process in the biogenic sludges.

That’s why Weber Entec has developed the BioPush reactor. The innovation of this approach is that the ultrasound is fixed on the outside of the reactor and thus no disrupting/interfiering body is left in the medium to be treated.

The BioPush Technology

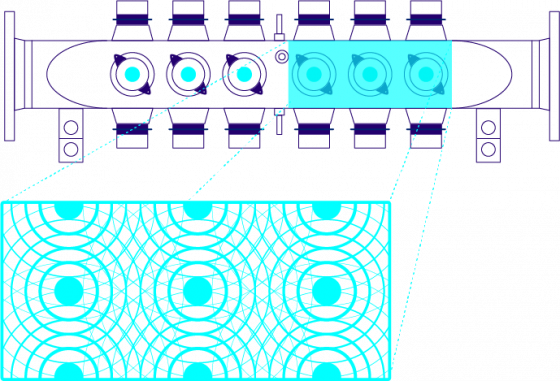

Through its high-performance surface transducer, the BioPush reactor generates a homogeneous cavitation field within the reactor. The reactor body is rectangular and hosts 6 ultrasound transducers on each side. The 24 ultrasound elements cause the entire body to “swing” with a frequency of around 22 kHz, which virtually quadruples the amplitude.

The effect of the sludge is at least as high as with the standard rod transducer technology but the entire reactor is 100 % maintenance free and has a durability of three years and more. Even problematic substrates such as highly thickened mixed sludges from waste water treatment plants or from agricultural fermentation plants are treated at maximum performance. In traditional ultrasonic reactors, there is usually direct contact between the sonotrode and the substrate, and this inevitably results in continual gradual wear of the sonotrodes. At the start, these plants often produce the same performance as the BioPush, but this rapidly falls off noticeably, because tressing builds up rapidly on the sonotrodes, which are inevitably damaged by cavitation, and this causes damping even to the extent of complete acoustic insulation.

Technical Characteristics of the BioPush Reactor:

- Up to 25 % more biogas (proven many times over)

- 2,000 W ultrasound performance per ultrasonic reactor

- Treatment of substrates with up to 15 % solids content

- Mechanical pretreatment optional

- Easy adaption to dynamic flow rates

- Optimum energy input thanks to homogeneous, contact-free sound field

- Compact structure

- Can be cascaded as desired

- Plug & play

To prove the homogenity, a metal structure wrapped with aluminium foil is placed into the with water filled reactor. After 15 s of ultrasound treatment, the structure will be taken out and the aluminium foil shows a homogenous destructions pattern on all four sides.

Plant control and remote access

A PLC-supported control system enables robust and trouble-free operation.

The drawing shows the simple and therefore error-free structure of DesiUS. The plant consists of a macerator, a screw pump, in this case two ultrasonic reactors, flow quantity measurement devices, and pressure and temperature sensors (two each). The control cabinet with the PLC control system may be installed in a remote location, or directly on the plant.

A REVIEW

traditional technology: rod transducers

In traditional systems, damping of the cavitation performance increases with the solids concentration. Frequently, therefore, biomass is treated only if it is in the immediate proximity of the ultrasound source.

Lasting time of rod transducers in sludge applications is between six month and two years, depending on the properties of the sludge. Additionally already after a short period of time, rod transducers require extensive maintenance.

2. Transducer after approx. 9 month in operation in a WWTP

Entec Newsflash

2-stage US plant

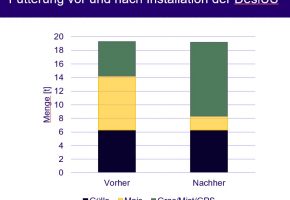

Feeding: 17 % corn 15 % solid cow manure 3 % grass 65 % liquid cow manure An ideal installation location for our ultrasound system was quickly…

Won tender about 28 kW US Plant at WWTP

Weber Entec won the tender for providing a sludge disintegration system for a WWTP in Lithuania. The Weber Entec ultrasound machine is installed since 2017 and equipped with 14…

4-stufige US Anlage

Feeding: 48 % corn 21 % solide chicken manure 17 % sugar beets 7 % whole-crop silage 7 % solid cow manure

3-stufige US Anlage

Feeding: corn 38% whole-crop 19% grain corn 13% beets 30%

4-stufige US Anlage

The planning begins with a study of the conditions and, if possible, the building plans of the biogas plant. At the end there is an individually manufactured ultrasound disintegration…

4-stufige US Anlage

Once again a not everyday Construction. In this biogas plant, a crane was specially organized because it had to go through the roof of the pump room. As a reward…