Optimization of your waste water treatment plant

The expectation of operating waste water treatment plants as energy-independently as possible increases the pressure on local authorities and plant operators, not just financially, but increasingly also politically.

However, it is not possible to achieve this aim by means of the “classical” fermentation process, in spite of mature technologies. Additional expenditures, such as the acceptance and fermentation of high energy value co-substrates in terms, are one of the options which are increasingly used. A further method, which is highly efficient and linked to low costs is the disintegration of sewage sludge by means of ultrasound. It is precisely the ultrasonic treatment of the difficult to ferment surplus sludge which breaks up the flocculated structure and opens up the cells, resulting in a significant increase in efficiency and in process optimisation of the treatment plant.

You will find a detailed description of the cavitation effect under: “about ultrasound”.

- Gain of electric and thermic energy

- Reduction of disposal costs

- Saving of auxiliary substrates

- Improved digester agitation

- Improved CO2 footprint

- Savings on external carbon sources

- Avoidance of bulking sludge

- Avoidance of foam problems

Disintegration by ultrasound

Disintegration means the breakdown of biogenic sludge into minute particles by external forces.

The resulting increase in surface area causes an acceleration of the organic breakdown process, and thereby results in an increased biogas yield. In addition, the release of exoenzymes from the external cell layer increases the enzyme activity in the digester. In ultrasonic disintegration, the electrical oscillations created by a generator are transformed by a converter (sonic transducer) into mechanical vibrations. These vibrations are transferred into the surrounding medium by means of a device known as a sonotrode. Following the rhythm of the ultrasonic frequency, they cause high alternating positive and negative pressure phases, depending on whether the oscillator is expanding or contracting at the time. During the negative pressure phase, microscopical cavities are formed in the liquid exposed to the ultrasonics; these then collapse in the subsequent positive pressure phase.

This process is known as cavitation. From the implosion, which releases high pressures and temperatures, strong impact and shear forces occur in the area immediately around the cavities, and these cause the surrounding micro-organisms to disintegrate.The core of the DesiUS is the ultrasonic technology from Weber Ultrasonics. The BioPush reactor developed specifically for the treatment of biogenic slurries fulfils the demanding requirements of the disintegration process, and in many aspects is significantly better suited than the usual rod transducers or sonotrode technology.

Bulking and floating sludge

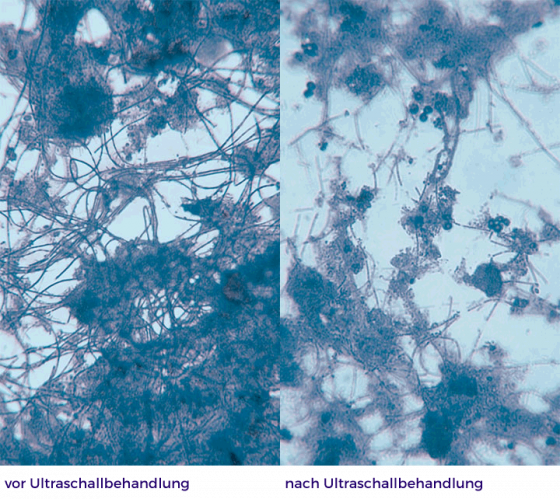

These are biologically determined phenomena attributable to the proliferation of filamentous organisms in masses.

For some years, increasing problems with bulking and floating sludge, and the tendency of sludge to foam, have been observed at many WWTPs in Germany designed for the activated sludge process. In these circumstances, the disintegration of return sludge produces the following effects:

- Destruction and reduction of filamentous micro-organisms

- Improvement of sludge sedimentation during secondary clarification

- Minimisation of foaming problems during fermentationThe

The visual differences in the fibrous structure before and after ultrasonic treatment are evident in the images below.

Climate protection

The disintegration of sewage sludge makes a contribution to climate protection

The approximately 10,000 public waste water treatment plants in towns and communities require a large amount of energy. With a quota of 20%, they are amongst the largest consumers of power in the public sphere. The overall power consumption of the treatment plants is approximately 4,400 Gigawatt hours per year. This corresponds to an annual CO2 emission of 3 million tonnes [1].

The ultrasonic disintegration of sewage sludge improves the anaerobic stabilisation, which is used in three quarters of all public waste water treatment plants. A more rapid and thorough breakdown of the organic material in the sewage sludge results in an increased production of gas, which can be used as an energy source in combined heat and power plants. The energy consumption of the disintegration module, and the additional ventilation energy because of an increased backload, appear as negative entries in the energy balance.

The calculations below show that the use of the Smart DMS disintegration module results in a significant improvement in the energy balance of waste water treatment plants, and can therefore provide a valuable contribution to the minimisation of CO2 emissions.

Areas of Application and Aims of Disintegration

In the majority of large public waste water treatment plants, the sewage sludge is subject to anaerobic treatment, which under suitable conditions is accompanied by stabilisation. At the present state of knowledge, the anaerobic breakdown of organic material takes place in four phases, and its end products are water, methane, and carbon dioxide. In the initial, phase, hydrolysis, polymeric substrates are split by exo-enzymes into dissolved lower molecular weight components. This degradation step limits the rate of the entire anaerobic breakdown process. Suitable processes such as ultrasonic disintegration make it possible to promote the limiting hydrolytic breakdown step.

The definition of disintegration is that the sludge is broken up by external forces into minute particles. Depending on the intensity of the input energy, these forces result in a breakdown of the floccular structure of the sludge, a release of exo-enzymes, through to opening up of the micro-organisms in the sludge.

The released organic substances are more easily accessible, both to anaerobic and aerobic breakdown. The area of application therefore reaches from the intensification of the anaerobic stabilisation by disintegration of the surplus sludge, to minimisation of surplus sludge production or improvement of the denitrification capacity by disintegration of the return sludge, through to the targeted treatment of activated sludge in order to reduce fibrous bacteria.

Precisely with regard to the energy gain associated with an intensification of the anaerobic stabilisation and increased gas production, this application is of particular interest, and will be dealt with subsequently in more detail.

DesiUS (Disintegration Ultrasound System) represents energy-efficient and process-robust cell opening technology combined with exceptionally high efficiency. The robust and completely maintenance-free construction of the BioPush reactor allows a simple and uncomplicated structure. The ultrasonic reactors of the turnkey constructed plant are charged via a screw pump. The substrate is routed through the sound field at a specific speed in such a manner that the specific energy input required for treating the substrate is ideally achieved. A macerator protects the machine from foreign objects and provides coarse homogenization upstream, in order to achieve optimal coupling of the ultrasound. A PLC-supported control system enables robust and trouble-free operation. In addition, the machine is equipped with sensors that monitor temperature, pressure and volumetric flow.

Our Service

- System analysis to verify potential of cost reduction in sewage sludge operations

- System analysis to determine the use of sludge disintegration to ght bulking sludge

- System analysis to identify potential Balance of materials

- Planning, construction and installation of an adapted disintegration module

- Measurement and process technologic support while transition into continuous operation

- Process optimization

- Offer and implementation of a “turn key” solution without hidden costs

- DesiUS – high requirements imposed on effectiveness and operational reliability

Entec Newsflash

Biogas Power-ON

Meet us at Biogas Power-ON in Copenhagen. We present at the conference and a site visit is organized to one of our reference plants.

Business of Biogas

Meet us at Business of Biogas in St. Louis, MO.

Installation options for DesiUS

Delivered turnkey in containers or assembled directly on-site in intricate pump rooms - everything is possible. Our system can be delivered in both small 10" and larger 20" containers. The…

Our Bestseller – The turnkey containerized system

Our bestseller: the turnkey system, ready for immediate use. Simply connect the piping and plug in the power – it couldn't be quicker or more convenient. Fully assembled in our…

SIWW

We exhibit on the SIWW - Singapore International Water Week - Meet us at German Pavillion, B2-Q17

IFAT

We exhibit on the worlds largest environmental technology exhibition in Hall A2, booth 240

2-stage US plant

Feeding: 17 % corn 15 % solid cow manure 3 % grass 65 % liquid cow manure An ideal installation location for our ultrasound system was quickly…

Won tender about 28 kW US Plant at WWTP

Weber Entec won the tender for providing a sludge disintegration system for a WWTP in Lithuania. The Weber Entec ultrasound machine is installed since 2017 and equipped with 14…

4-stufige US Anlage

Feeding: 48 % corn 21 % solide chicken manure 17 % sugar beets 7 % whole-crop silage 7 % solid cow manure

3-stufige US Anlage

Feeding: corn 38% whole-crop 19% grain corn 13% beets 30%