COST AND PROCESS OPTIMIZATION WITH ULTRASOUND

Savings through Ultrasound at the Großenwiehe Biogas Plant

The Initial Situation

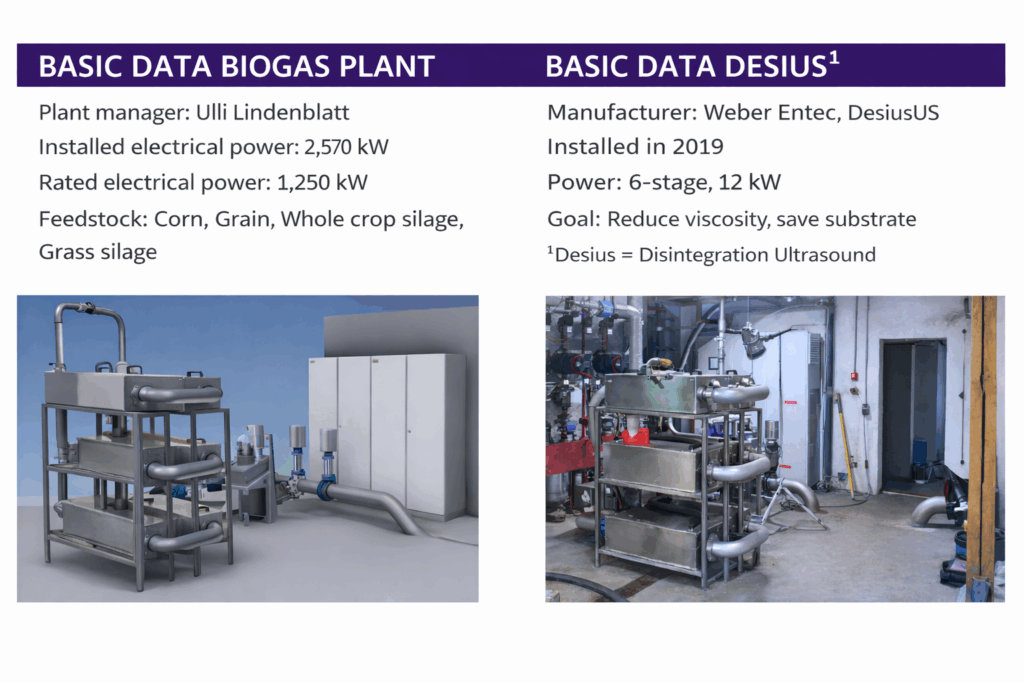

Großenwiehe GmbH & Co. KG operates a 1.250 kW dry fermentation plant near Flensburg. The biogas facility is double-roofed and is primarily fed with maize, whole-crop silage (WCS), and grass.

Due to the high viscosity in the fermenters, operational issues repeatedly occurred at the biogas plant.

In May 2019, a six-stage ultrasonic system supplied by Weber Entec was installed. The primary objective of operations manager and co-partner Ulli Lindenblatt was to reduce the viscosity in the fermenters.

The Installation

The ultrasonic system was integrated into the two main fermenters that are regularly fed. An intelligent valve control system alternately treats Fermenter 1 and Fermenter 2.

The results are impressive!

Key figures at a glance

Ulli Lindenblatt’s Experience – Detailed Description in Words

- Substrate Savings:

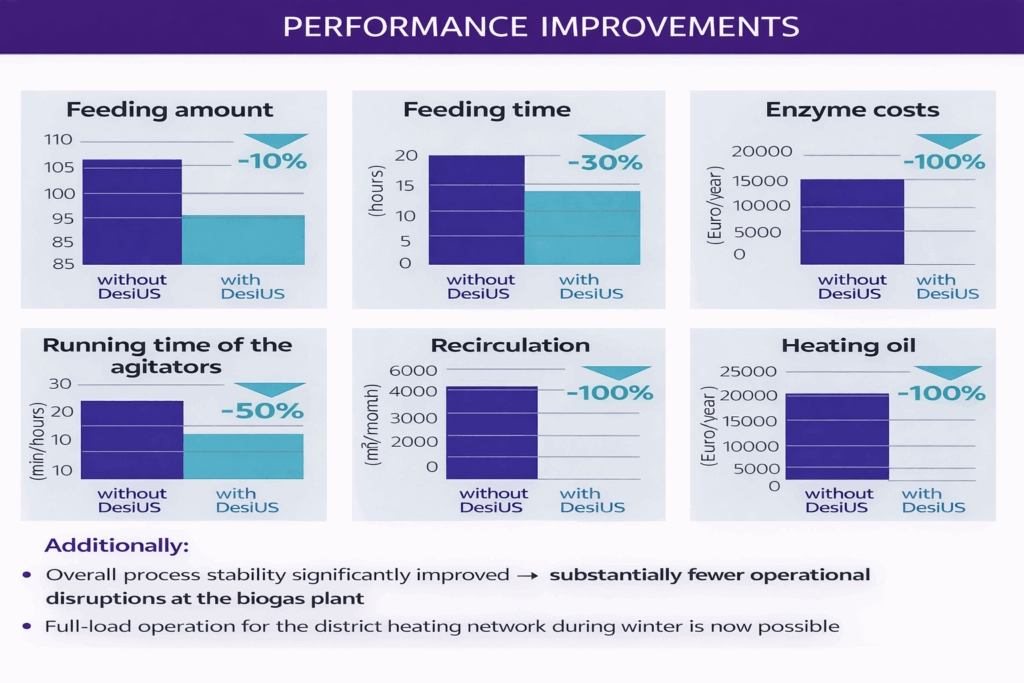

Mr. Lindenblatt compared the feeding data and gas yields from December 2018 (without DesiUS) with those from December 2019 (with DesiUS) and identified feed savings (maize + whole crop silage) of 10%.

- Enzyme Savings:

Großenwiehe has completely eliminated the addition of enzymes. Previously, enzymes had to be added to maintain adequate mixing capability and process stability. Annual cost savings amount to €15,000.

- Savings in Agitators I:

The operating times of the agitators were reduced by 50%, from 28 minutes per hour to 14 minutes per hour.

- Savings in Agitators II:

Wear on the agitators has been reduced. Typically, one agitator had to be replaced every winter. Last winter and up to the present day, no agitator replacement has been necessary.

- Savings in Pumps:

The pump and the screw conveyor now operate approximately 30% less during feeding intervals. This is due to the reduced viscosity in the fermenter, allowing the screw conveyor to introduce feed into the fermenter more quickly. Operating time was reduced from 20 hours per day to 14 hours per day.

- Recirculation:

Previously, approximately 5,000 m³ per month had to be recirculated from the secondary digester back to the fermenter in order to reduce the total solids (TS) content and maintain process stability. Since commissioning DesiUS, no recirculation has been required. The secondary digester is once again functioning as a true post-digester.

- Savings in the District Heating Network:

In winter, heat production for the district heating network (supplying households and businesses in the village) could not always be covered 100% by the biogas plant (BGP).

As redundancy, the operator maintained an oil-fired heating system. In some winters, heating oil costs reached up to €50,000, with an average of €20,000 per winter. Following the installation of DesiUS, the reduced viscosity allows the biogas plant to operate at higher feeding rates and therefore higher output when required. Sufficient heat is now available. Heating oil costs have been eliminated entirely.

The Digestate:

Farmers who apply the digestate have observed less fibrous structure and a significantly lower total solids (TS) content. This provides advantages during spreading and indicates improved substrate disintegration and degradation, resulting in higher specific gas yields.

Process Stability:

Overall process stability has increased. Mr. Lindenblatt reports significantly fewer malfunctions, as the plant operates more smoothly; pumps run more easily and agitator operation has been reduced.

This is what Ulli Lindenblatt says 1.5 years later

I am Ulli Lindenblatt, co-shareholder of the dry fermentation biogas plant BGA Großenwiehe near Flensburg.

I chose DesiUS

…because after flexibilization, during winter feeding at double output, we repeatedly experienced problems with viscosity and volumetric loading.

This is how I benefit from that decision today

…we were able to cut the agitator running times in half and additionally save a good 10% in feed…

Something I would never have expected before

…that we could save almost 200 m³ of recirculation per day and still reduce the viscosity in the fermenter with the help of DesiUS.

My tip to anyone interested in DesiUS

…with DesiUS, you increase the process stability of your biogas plant, especially when using challenging substrates such as grass and whole crop silage (WCS).

Conclusion

Following the installation of DesiUS, Großenwiehe GmbH & Co. KG was able to reduce operating costs of the biogas plant (BGP) in various areas. The process stability of the plant has been sustainably improved, resulting in fewer costly malfunctions.

With his ultrasonic system, Mr. Lindenblatt has demonstrated impressively what is possible beyond substrate savings through ultrasound technology. He has been able to solve numerous operational challenges for himself and his plant and is therefore very well positioned for the future.