INCREASE THE EFFICIENCY OF YOUR BIOGAS PLANT

No other mechanical form of energy is as efficient in working on the cell structure of the biomass.

Regardless of whether more biogas is to be generated or whether feed substrate is to be saved while performance remains constant – with the turnkey and almost maintenance-free ultrasonic disintegration machines from Weber Entec, you can significantly increase the efficiency of your biogas plant, and do so within a payback period of typically less than 3 years (and often much less than that!).

Profits from biogas plants are reduced by increasing substrate and operating costs, while feed-in tariffs at best stay the same – and this can frequently threaten the operator’s existence. In the medium term, almost every biogas plant will have to perform substrate preparation of some description. In this case, the ultrasonic disintegration machine technology from Weber Entec is recommended as a particularly cost and performance effective repowering measure.

Opening up the cell structure accelerates the biology significantly. This is equivalent to a “virtual increase in digester size”. The logical consequence is optimised substrate exploitation which results in a significant substrate saving for the same biogas yield. In addition, the methane content of the biogas increases by typically one to three percentage points.

The physical working principle of ultrasound is the cavitation effect. You will find a detailed description of the process here:

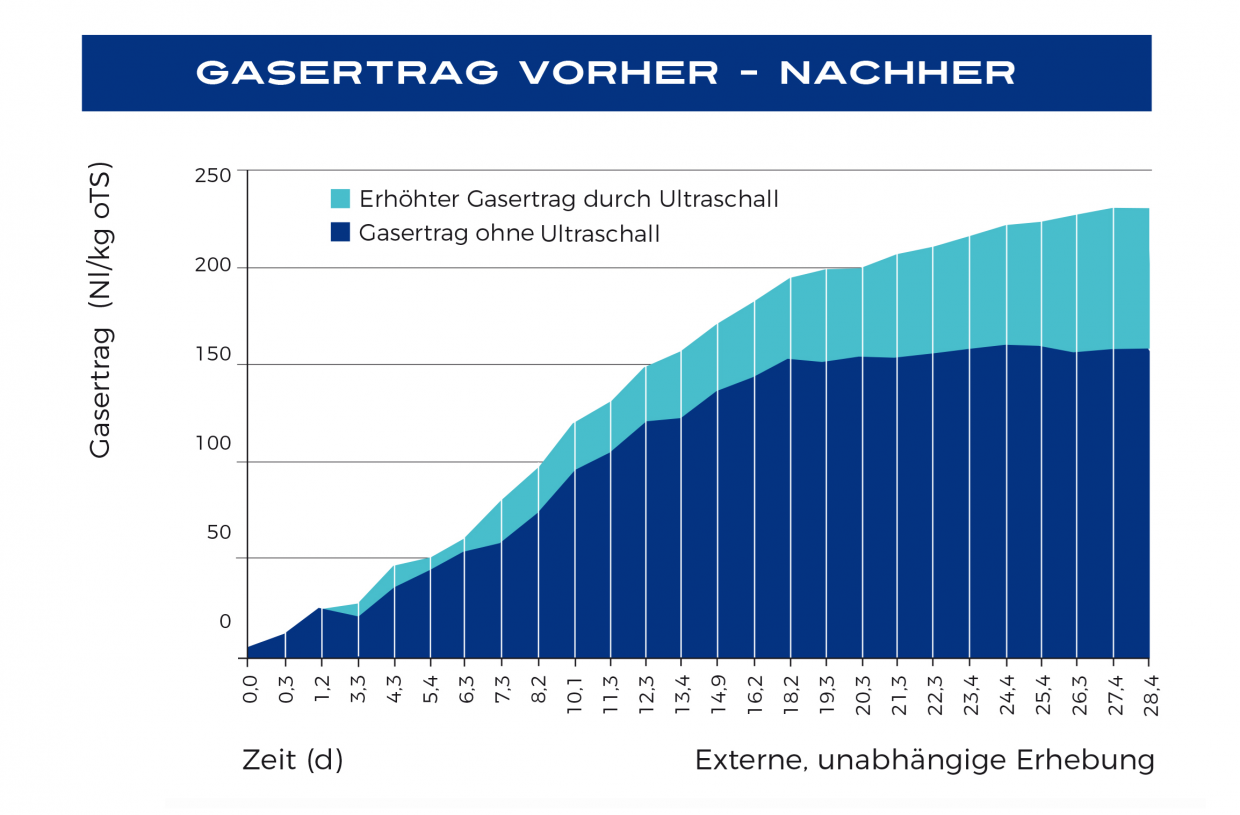

- Increased gas yield / substrate savings

- Significantly increased degree of degradation

- Stabilisation of biology

- Improved flow properties

- Avoidance of floating layers

- Reduced agitator wear

- Reduced energy requirement for pumps and agitators

- Use of substrates that are difficult to process but often cheaper can be increased

- Operational reliability of the biogas plant is increased

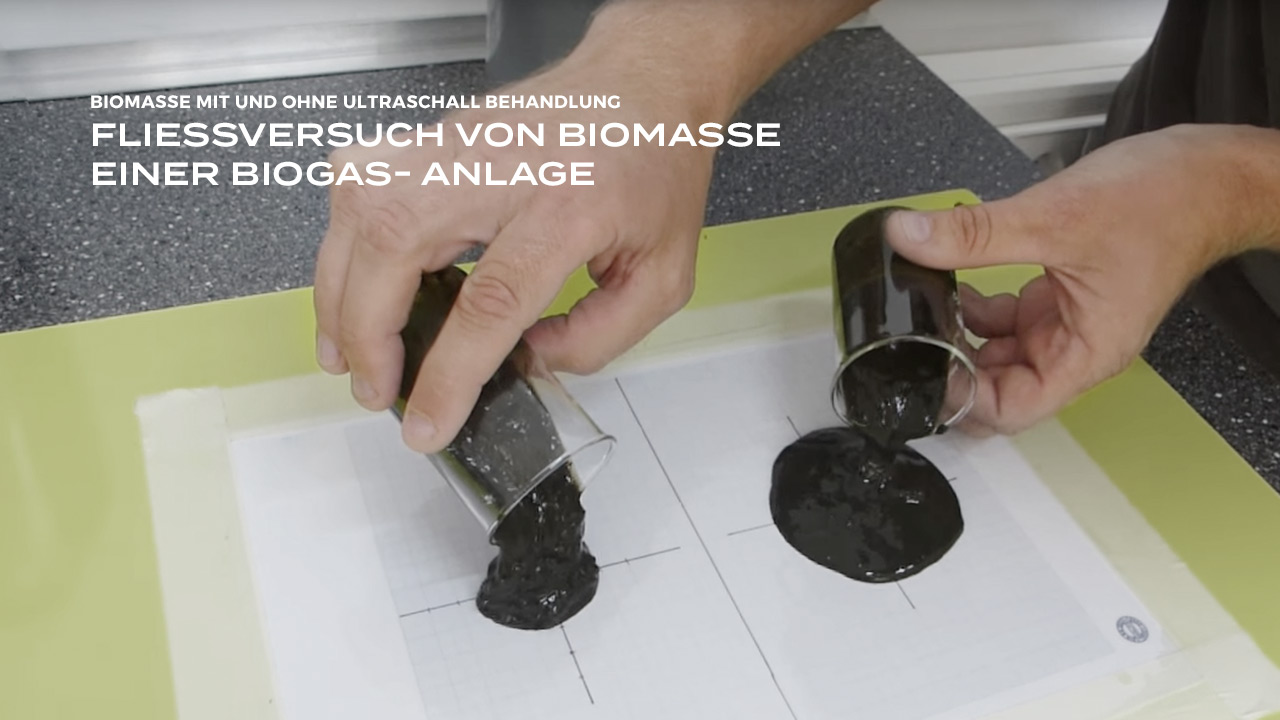

FLOW PROPERTIES

with ultrasound disintegration

Another effect of the ultrasonic disintegration is to improve the viscosity of the substrate.

In this video, the direct comparison of flow properties between untreated and treated substrate is shown after the initial startup of the ultrasound disintegration plant. Both samples are identical (substrate, temperature, etc). The only difference is the sonication.

Find out about the options for increasing efficiency by using ultrasound to suit your individual requirements, and get a calculation of an efficiency balance by entering some key data for your biogas plant.

Gas yield before - after

Construction equipment engineering

The term “DesiUS” stands for “disintegration ultrasound system”. The disintegration process which forms the basis of DesiUS was developed by Weber Ultrasonics in collaboration with the Fraunhofer Institute, and was optimised by Weber Entec through the use of the BioPush reactor.

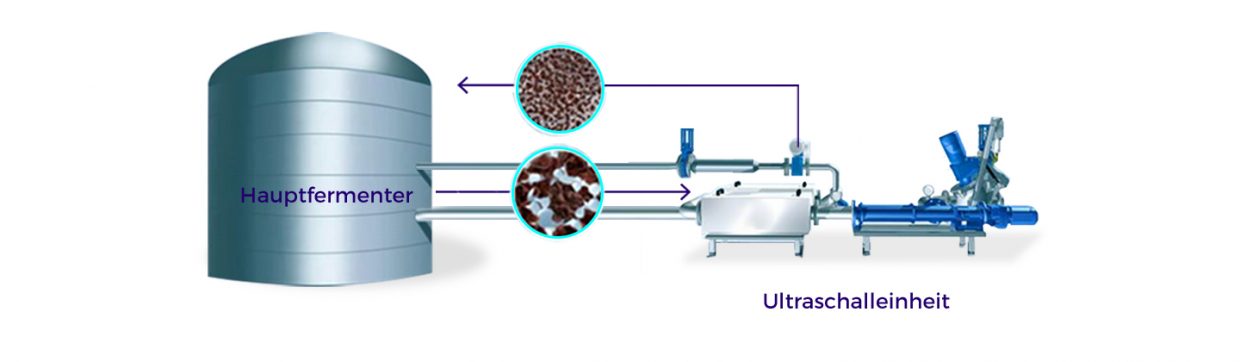

DesiUS (Disintegration Ultrasound System) represents energy-efficient and process-robust cell opening technology combined with exceptionally high efficiency. The robust and completely maintenance-free construction of the BioPush reactor allows a simple and uncomplicated structure. The ultrasonic reactors of the turnkey constructed plant are charged via a screw pump. The substrate is routed through the sound field at a specific speed in such a manner that the specific energy input required for treating the substrate is ideally achieved. A macerator protects the machine from foreign objects and provides coarse homogenization upstream, in order to achieve optimal coupling of the ultrasound. A PLC-supported control system enables robust and trouble-free operation. In addition, the machine is equipped with sensors that monitor temperature, pressure and volumetric flow.

- Very high energy efficiency – 50 % saving compared to other disintegration systems

- Extremely low-maintenance plant technology

- High degree of operational reliability

- Long standing times

- Can be ideally adapted to the respective requirements

- Lower space requirement thanks to compact design, simple plug & play installation

- Quick pay back

Possible integration

Plant control and remote access

A PLC-supported control system enables robust and trouble-free operation.

The drawing shows the simple and therefore error-free structure of DesiUS. The plant consists of a macerator, a screw pump, in this case two ultrasonic reactors, flow quantity measurement devices, and pressure and temperature sensors (two each). The control cabinet with the PLC control system may be installed in a remote location, or directly on the plant.

Advantages of BioPush

Long lifetime, operational reliability, zero maintenance

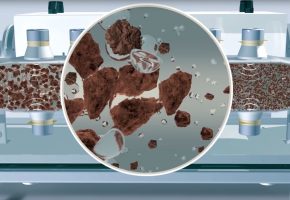

The BioPush Ultrasound reactor solves the problems of the other disintegration systems. Because biomasses with a typical solids content between 8% and max. 13% have a relatively high viscosity, more effort is usually required in traditional plants in order to ensure an effective coupling of the ultrasound to the medium. Because the cavitation performance of the ultrasound becomes more damped as the viscosity of the medium increases, the medium must therefore be passed as close as possible to the sonotrode. Although this could be achieved constructionally by means of a sufficiently small pipework cross-section, it is not possible to implement it in this way, because the sonotrodes tend to become affected by blocking and “tressing” from fibrous components, both in substrates from biogas plants using renewable raw materials and also in sewage sludges. The results are a high level of sound damping, and therefore reduced energy efficiency.

The BioPush reactor developed by Weber Entec specifically for the treatment of biomasses tackles this problem. The structure practically precludes blockages and tressing. The working life of the BioPush reactor is several times longer than with classical rod sonotrodes in the biomass area.

Our Service

- System analysis for determining the potential for reducing operating costs associated with biomass

- Planning, manufacturing, installation and commissioning of a customised disintegration system

- Measurement and process technologic support while transition into continuous operation

- Process optimisation

- Analysis calculations

- Quotation and implementation as a turnkey solution – no hidden costs

- Leasing models available

- Personal, competent and non-binding advice at any time

Entec Newsflash

Installation options for DesiUS

Delivered turnkey in containers or assembled directly on-site in intricate pump rooms - everything is possible. Our system can be delivered in both small 10" and larger 20" containers. The…

Our Bestseller – The turnkey containerized system

Our bestseller: the turnkey system, ready for immediate use. Simply connect the piping and plug in the power – it couldn't be quicker or more convenient. Fully assembled in our…

2-stage US plant

Feeding: 17 % corn 15 % solid cow manure 3 % grass 65 % liquid cow manure An ideal installation location for our ultrasound system was quickly…

Won tender about 28 kW US Plant at WWTP

Weber Entec won the tender for providing a sludge disintegration system for a WWTP in Lithuania. The Weber Entec ultrasound machine is installed since 2017 and equipped with 14…

4-stufige US Anlage

The planning begins with a study of the conditions and, if possible, the building plans of the biogas plant. At the end there is an individually manufactured ultrasound disintegration…

New installation

substrate savings

Ultrasound disintegration

Repowering at Biogas & Waste water treatment plants

Installation of another plant

… und wieder geht eine Ultraschallanlage von Weber Entec ans Netz!

Open day for visitors biogas plant Techentin

On September 15, we were on the open day at the biogas plant in Techentin. Our ultrasound disintegration plant DesiUS…